Table of Contents

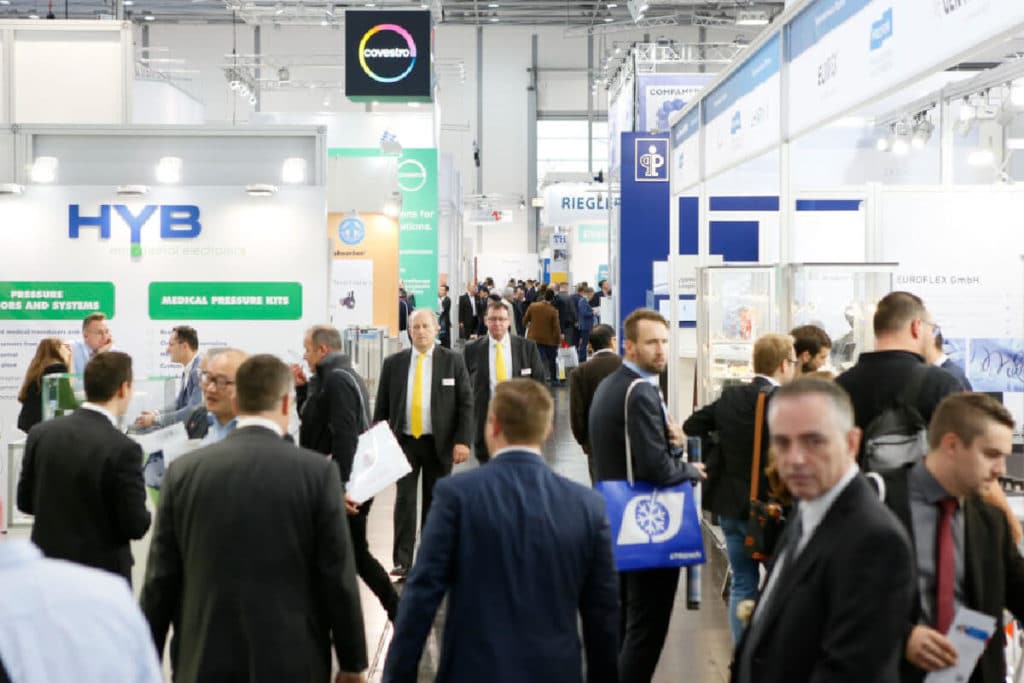

After COMPAMED, the international leading event for suppliers of medical technology, could only be held digitally due to the pandemic last year, it will now be held in-person again at Messe Düsseldorf from 15 to 18 November, at its fixed runtime in parallel with the world leading medical trade fair MEDICA.

Almost 500 registrations from exhibitors prove that there is a high level of interest from medical technology suppliers, which is a huge step towards reaching normality again. In accordance with the hybrid event concept, significant programme components such as the COMPAMED HIGH-TECH FORUM from the IVAM International Microtechnology Business Network which specifically focuses on the microtechnology and nanotechnology sectors and the COMPAMED SUPPLIERS’ FORUM from Devicemed, which covers the entire development and production sector in medical technology, will be offered as both online (as a live stream) and in-person events which can be accessed by purchasing the relevant ticket.

In contrast to the previous years, COMPAMED will be held in Halls 13 and 14 this year (instead of Halls 8a and 8b). By moving the event to new halls, Messe Düsseldorf is meeting the wishes of the federal state government of North Rhine-Westphalia, namely to ensure that they can continue to use the north area of the trade fair centre for activities in conjunction with the COVID-19 vaccination campaign.

Supply bottlenecks

Both the omnipresent COVID-19 pandemic and its consequences will provide much food for thought: “Due to the impact of the corona crisis, supply bottlenecks have occurred: flight and seaborne transportation cancellations have led to huge supply bottlenecks, particularly for electronic products.

During the crisis, this was exacerbated by unnecessary stockpiling. Companies bought and stored more components than they needed to ensure that they were safe because they were scared of experiencing a shortfall in supply”, explains Dr. Thomas R. Dietrich, CEO of the IVAM International Microtechnology Business Network. Raw materials and individual components were also scarce, because the industry recovered more quickly than many suppliers expected it to. However, this will return to normal within a short period of time.

Computer chips

Computer chips were in short supply during the crisis because medical technology suppliers in particular suddenly needed far more of them. Dr. Meinrad Lugan, CEO of BVMed, recently put the situation into perspective: In many sectors, the issue was not shortages in terms of quantity, but instead distribution issues. Lugan notes that there was a “trend to make huge excess orders or multiple orders”.

The resulting supply bottlenecks should be combated using “smart digital solutions based on existing eStandards”. According to IVAM, internationalisation of the economy would still be expedient, as the global supply chains could not be maintained, which is the opposite of constructive. European manufacturers need the option to carry out production at a lower cost in other countries in order to remain competitive.

These producing countries, in turn, need European customers in order to keep their own economies running. According to IVAM, there should, however, still be local supply chains for critical components – particularly for sensitive products that are important for basic care of the entire population, e.g. in the healthcare sector.

One topic continues to cause a huge stir…

Another topic also triggered huge upheaval in the industry: On 26 May 2021, the new European Medical Device Regulation (MDR) and the equally new Regulation on In-Vitro Diagnostic Medical Devices (IVDR) came into force.

“The survey results show that the EU MDR continues to be very challenging, expensive and time-consuming for companies”, states Veronika Schweighart, COO at Climedo Health. The IVDR also increases effort and costs for companies. Along with new products, all approved products which are already available on the market need to undergo recertification in accordance with the regulation. In addition to this, the notified bodies must be put through a new notification procedure, which has not yet been finalised.

Current developments throughout the entire process chain

Current developments throughout the entire process chain will be presented in a hands-on manner: mechanical and electronic components have their moment in the spotlight in the expert talks, along with innovative basic materials, manufacturing processes, all types of contract manufacturing, design and usability aspects and quality assurance. Keynote speeches on new markets complete this diverse programme.

Additive manufacturing for custom implants for patients

Additive manufacturing and robotics remain exciting themes in medical technology. Toolcraft AG sees itself as a pioneer of future-oriented technology such as additive manufacturing and in the construction of individual robot cells. As a partner for complete solutions, the company offers the entire process chain, from the concept to manufacturing to qualified precision components using additive manufacturing, machining and injection moulding, electrical discharge machining and mould making.

The many highlights of IVAM in Hall 13

The IVAM International Microtechnology Business Network is once more one of the cooperation partners for and biggest exhibitors at COMPAMED.

These include, in particular, printed electronics and highly integrated diagnostics for the next generation, “Equipment manufacturer meets component manufacturer”, laser and photonic applications, smart sensor solutions and microfluidic options to resolve challenges in point of care diagnostics and the life sciences.

Measuring blood pressure with an optical sensor

Highlights on the IVAM stand include new sensory developments. Conditions involving the cardiovascular system are among those which are most frequently cited as a cause of death in the industrialised nations. An important indicator for this is high blood pressure, which is currently still diagnosed and monitored by regularly taking blood pressure mechanically using an upper arm cuff. This method is uncomfortable and limits the patient in their daily activities, and, in comparison to other methods, only delivers a few selective measured values.

An optical sensor can provide help here. This sensor, which works using the basic principle of photoplethysmography (PPG), records the fill level of the blood vessels in the skin over time. Using the contour curve (pulse waves) recorded in this manner, a patented procedure is used to identify relevant points in time to determine the cycle of the pressure wave in the aorta, which enables conclusions to be drawn on changes in central blood pressure. In addition to offering an alternative to classic cuff measurement, the process also gives a blood pressure result for each individual heartbeat.

High-tech communication between the body and modern IT

With its next-generation electrode design, CorTec creates new pathways for communication between the body’s own electric signals and modern information technology. This young medical technology company specialises in developing efficient technology for active implants for recording over long periods of time and stimulation of neuronal activity.

A world first for stoma care

Optima Life Science and Optima Automation will present a world first when they participate in COMPAMED 2021 together – the first continuous manufacturing machine for stoma flanges. These are used as care products for artificial openings used to divert waste from the intestines (stoma). Thus, Optima Life Sciences now also offers an appropriate machine solution for stoma producers. The main advantage is that it brings two separate converting processes together in one line. Process stations that could previously only be operated in cycles were developed for this line.

Innovative microtechnology that serves the pharmaceutical industry

Another example of high-tech that conclusively demonstrates the expertise of the COMPAMED exhibitors are the micro annular gear pumps from the manufacturer HNP Mikrosysteme. Microencapsulation is also growing in significance in the pharmaceutical industry. Precise dosing techniques which can dose miniscule quantities are a prerequisite for manufacturing and processing APIs (Active Pharmaceutical Ingredients). Manufacturing these APIs is demanding as these substances, which can be anywhere on a scale from watery to oily, need to be handled very delicately.

Further information: go to COMPAMED newsroom